Ok - that's all it takes - I just didn't want to post into empty space ...

Preamble: I've got a Hunter multi-fuel woodburner - one of those big 'uns with double doors - it's supposed to run the central heating as well as the house - but all it does is heat the sky directly above my house. I can feed it with hundreds of £'s-worth of coal, and still shiver. 95% of the heat goes straight up the chimney - well sod that - I've had enough ...

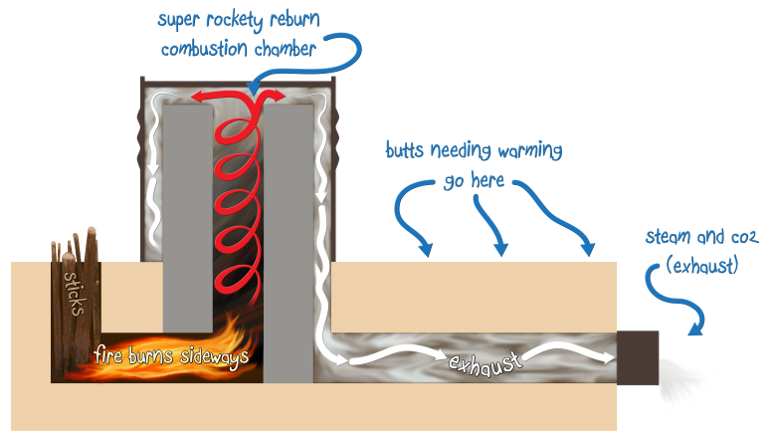

There are many videos and websites devoted to rocket stoves, so I worked my way through a few last year ... and to be honest I was a bit skeptical about the claims being made - but I thought I'd make one for as little cost as possible, if only to test those claims. Now I fully accept that ceramic construction is the way to go - but I've got steel, and I can weld - so steel it will have to be at this stage.

The first job is to find a suitable container - I chose a 47kg propane tank - and removed the valve (there are much easier ways than belting it with a hammer that some videos show) before filling the tank with water - which is ESSENTIAL - before cutting it open with an angle grinder. I then fabricated a firebox and welded that in place ... which takes us to the first pic:

This is where I got to last year, before running out of time:

So the next job was to weld on a 4" s/s riser tube:

I then surrounded that with a 6" tube and dropped some fire cement down to the bottom to hold it in place, and filled the cavity with perlite. This shows a small fire being lit in order to 'cook' the fire cement:

Now - this is the best bit: Look - no smoke ! Ok , it did smoke for a few minutes until it got up to temperature - but from then on, zero smoke.

I was so chuffed at this that I quickly plonked the top on, and lashed up a flue - which was not strictly necessary, but I wanted to simulate 'the real thing', as a test:

Just a handful of pieces of scrap wood, and the tank became so hot, there was no way it could be touched - at one point even some of the paint started burning off. But that was enough as a test - as I didn't want to stress half-set cement so early on.

There's just a few more jobs to do - I welded on some handles this afternoon, to make inspection/cleaning etc easier, and I need to do more work on the firebox door tomorrow.

But - this technology really does work - it's not exaggerated as I suspected it might be. It really is possible to heat a house with 1/10th the wood of a conventional wood-burner, that is already very clear.

LJ